描述

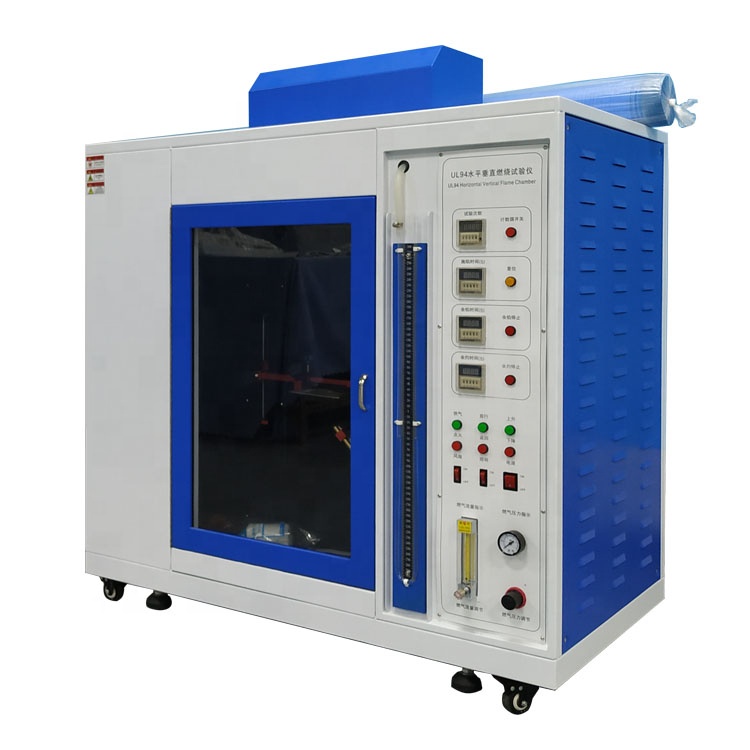

UL94 Horizontal-Vertical FlammabilityTester is a fully automatic instrument contained in its own cabinet to maximize the safety of the operator. It screening procedure for comparing the relative burning behavior specimens made from plastic and other non-metallic materials, exposed to a flame ignition source of 50W or 500W nominal power. These test methods determine the linear burning rate and the after flame/afterglow times, as well as the damaged length of specimens. They are applicable to solid and cellular materials that have an apparent density of not less than 250kg/m3, determined in accordance with ISO 845. Then do not apply to materials that shrink away from the applied flame without ignition; ISO 9773 should be used for thin flexible materials. And the combustion test device of plastic materials represented by UL-94. It can perform each test of HB, V0 to V2, 5V and VTM, HBF.

Standards:

UL94: Test for Flammability of Plastic Materials forParts in Devices and Appliances

GB / T2408: Plastic – Determination of burningcharacteristic – Horizontal and Vertical Test

ISO9722: Cellular plastics — Determination ofhorizontal burning characteristics of small specimenssubjected to a small flame

ASTM D4986: Standard Test Method for HorizontalBurning Characteristics of Cellular PolymericMaterials

IEC60695-11

Features:

Horizontal and vertical flammability chamber is composed by the test part and control part, using the integrateddesign, to facilitate the installation at the scene and debug. The shell of the test chamber and the important partsare all manufactured by stainless steel, resistant cigarettes and gas corrosion. The automatic degree of controlsystem is high. Has automatic ignition, the products which were tested in both vertical and horizontal orientationhas the function automatically follow flame in the cross of the test. Time and temperature figures show, so thatthe observation and records is facilitate and the use of it is stable and reliable.

Structure:

Specifications:

Test room size

≥0.5CBM, with observation window

Casting time

0 ~ 999.9S can be set

Residual flame time

0 ~ 999.9S can be set

Afterburning time

0 ~ 999.9S can be set

Burning Angle

20 °, 45 °, 90 ° (0 °) is adjustable

Size of the burners

Nozzle Ø 9.5±0.3 mm, inner diameter nozzle effective length to 100 ± 10 mm, have air conditioning

Flame height

20mm to 175mm adjustable

Control System

PLC + Touch Screen auto & manual control + Printer

Product Features

Equip with Lighting fixtures, Exhaust gas installations, Gas flow regulating valves, Gas pressure gauges, Gas pressure regulating valves, Gas flow meters, Gas u-type pressure gauges and Sample fixtures

Power supply

AC 220V, 50Hz

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

UL94 Yatay ve Dikey Ayakla Test Cihazı, UL94 Yanma Test Cihazı

Marka:

SKU: CM-ZJBT7

Kategori: Analiz - Test

Güvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.