描述

Summary:

Small Loading Brinell hardness testing machine can reflect the overall performance of the materials, but cant be influenced by the sample organization and composition micro-segregation uneven, so it is a hardness test of high precision. It is widely used in metallurgy, forging, casting, without hardened steel and non-ferrous metals industries, laboratories, universities and scientific research units. It is the closed loop sensor loading, the electronic automatic loading system, has 10 levels test force. The machine has high precision, high repeatability and stability, easy operation.

Application Areas:

Suitable for the precision testing of parallel plane,

Stable and reliable for the curved surface testing .

Application Materials:

Measuring Brinell hardness of ferrous metals, non-ferrous metals and bearing alloys; soft metals, small and thin parts.

Features:

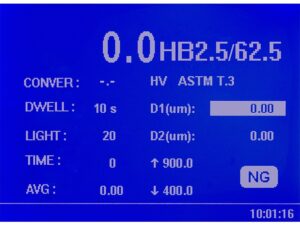

4 inches LCD display, Menu structure

With Motorized turret function

● Automatic test process, easy to operate

● High-definition optical system, light source brightness can be adjusted by 20 levels.

● With hardness value conversion function, hardness up and down tolerance judgment.

● Diagonal length D 1 and D 2 encoder input to reduce manual reading error.

● The objective lens and the pressure head can automatically switch and locate accurately.

● Test results and data processing, can be output through the printer.

Specifications

Product Name

Brinell Hardness Tester

Model

NG-HB62.5

Testing Range

Kgf

1, 5, 10, 15.625, 30, 62.5

N

9.807, 49.03, 98.07, 153.2, 294.2, 612.9

Measuring range

8-650HBW

Magnifications

Observing or Measuring 50X, Measuring 100X

Screen

LCD

Max Test Height

165mm

Min Measuring Unit

0.25um (depends on the optional object glass)

Load control

Automatic (loading, duration, unloading)

Data input

Built-in Printer

Distance of Indenter to outer wall

130mm

Power Supply

220V AC, 50 / 60Hz

Execution Standard

EN, ISO 6507, EN ISO 6506, ASTM E-384, ASTM E-10-08, ASTM

E-384 GB/T231.2,JJG150

Standard Accessories:

Name

Quantity

Name

Quantity

Main Unit

1

Accessory Case

1

Objectives (5X , 10X),

micrometer (10X)

Each 1

Diameter φ2.5、φ5、φ10 mm

Hard Alloy Steel Ball Indenter

Each 1

HBW/3000/10(150~250)

HBW/1000/10(75~125)

HBW/187.5/2.5(150~250)

Each 1

Large, Medium, “V” shaped Testing Table

Each 1

Diameter fastening screw

1

2A Fuse

2

Dust proof covering

1

Power Cable, Print paper

Each 1

HB Reference table

1

Users’ Manual

Each 1

Optional Accessories

XY work table、CCD measurement system

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

Küçük Yükleme 62.5 Dijital Ekran Brinell Sertlik Test Cihazı, Otomatik Brinell Sertlik Test Makinesi

Marka:

SKU: CM-TZRIZ

Kategori: Analiz - Test

Güvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.