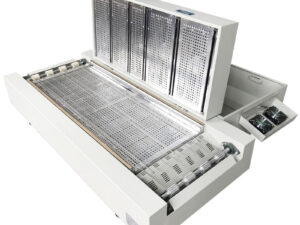

QRF830 infrared benchtop reflow oven is bigger size than QRF630 model SMT Reflow Oven solder welding .Which uses the PID temperature control system and rapid infrared heating technology controlling, so the temperature is being kept very accurate and evenly distributed. 8zones Hot wind , with cabinet power 3.5KW PID close cycle control size2440x680x1200mm

Description

Inquiry

Description

The QRF830 reflow oven infrared benchtop type is bigger size than QRF630 model SMT Reflow Oven solder welding .

Which uses the PID temperature control system and rapid infrared heating technology controlling, so the temperature is being kept very accurate and evenly distributed. The whole soldering process can be completed automatically and it is very easy to use. It is suitable for the board has chips and output is larger or the welding quality requirements are better.Designed with Multi-temperature curve choose.Four zones special temperature control mode more stable and precise.High quality thermocouple porcelain bead protect.Full-color HMI human-computer interface(touch screen).Super anti-temperature fan.Liner hearth use industrial grade anti high temperature and corrosion panel paint.PID microcomputer global temperature control system. High efficiency and energy saving finned heating tube.High temperature fan.Built in analog governor.

ModelQRF830Heat zone numbers8 zones(Up4, Down4)Heat methodHot windCooling zone numbersTwo natural air coolingLength of heating zone1400mmWidth of net belt300mmPCB size280mmHeight of net belt900±20mmTransport speed of net belt160~1350mm/min(Analog quantity adjusting)Transport direction of net beltLeft to right( right to left)Starting power11KWWorking power3.5KWInput supply powerThree-phase five-wire 380±10% 50HZHeat up timeAbout 20 minsTime of passing through the machine3.5 to 5.5 minsRange of temperature controlIndoor temperature to 400 degreesMethod of temperature controlPID close cycle controlNet weight250kgOutline size2440x680x1200mm

Dünya Çapında Teslimat

200'den fazla ülke ve bölgeye gönderim.

Güvenli Ödeme

Dünyanın önde gelen ödeme çözümleri.

%100 Para İade Garantisi

Birçok üründe 14 gün içerisinde koşulsuz iade politikası.

7/24 Teknik Destek

Her zaman bize istediğiniz yerden ulaşabilirsiniz.

Yardıma mı ihtiyacınız var?

QRF830 8 Bölge SMT Geri Geri Geri Geri Geri Dolap ile Kabine ile Kaynak

Marka:

SKU: CM-S7BTG

Kategori: Elektrik - Elektronik

Etiketler: China, customized, discount, hot wind, low price, made in China, manufacturers, QRF830, reflow oven, SMT Reflow Oven, solder welding, wholesale, with cabinetGüvenli Ödeme

SSL Şifreleme Teknolojisi ile işlem güvenliğiniz sağlanmaktadır.

Ayrıca kişisel veri güvenliğiniz ve ödeme bilgileriniz de en son teknoloji ile korunmaktadır.