Specification

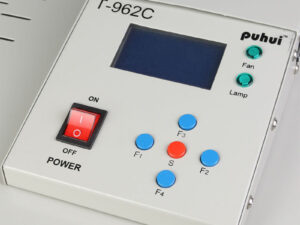

Program:

Microprocessor controlled, capable of holding 999 program sequences which may be run independently or in selected blocks for compound windings.

Control:

Spindle drive – High torque brushless DC induction motor producing a max torque of 78.5 Ncm.

Traverse – Constant current driven 4-phase stepper motor.

Features:

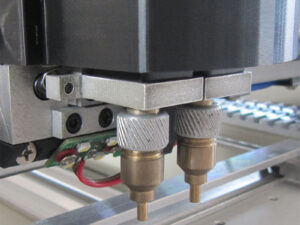

Wire guide is capable of holding four different sizes of wire at the work piece.

Application:

Small transformers e.g. ISDN, audio, voltage etc. and all other wound products requiring multiple windings

Package Includes:

Margin tape & cover tape attachments and wire feeder system, footswitch and comprehensive manual.

Wire size:

0.02 – 1.0 mm

Maximum Pitch:

10 mm

Winding Width:

110 mm (max)

Bobbin Diameter:

110 mm (max)

Max speed:

6000 and 3000 rpm versions available.

Power:

AC 230 / 110 V ± 10%, 50 – 60hz

Dimensions:

760 x 680 x 720 mm

Net weight:

37kg

CE cert.

No.AE9955093 01

Click for larger image

The WH-800 is a compact single spindle benchtop coil winding machine with digital control for semi-automatic operation. The wire guide system can present up to four different sizes of wire at the work piece ready for use – ideal for winding small transformers and other wound components that require multiple windings.

Margin and cover taping attachments conveniently mounted on the machine allow these operations to be carried out efficiently during the winding process with the minimum of handling.

The digital control regulates all of the fundamental winding parameters such as winding speed, wire pitch, acceleration, braking, and turns count. Using the simple programming system and multi-step programs, complex windings can be generated with ease. Stored programs can be instantly recalled, reducing machine setup time for product changeover to a minimum.

Please note that although the machine is fitted with two winding spindles, it is only possible to use the four-wire feeder system with one winding spindle.